Asphalt Color Coating | UV-Resistant, Eco-Friendly Road Resurfacing Solution

- Model

- PU-043

Review

Description

Information

Asphalt Modification Material

Our asphalt color coating is a water-based eco-friendly solution for revitalizing aged asphalt surfaces on roads, parking lots, and sports courts. It provides superior adhesion (Cross-Cut Test Class 1), high-temperature resistance (up to 80℃), UV fade resistance, and rutting resistance. With vibrant long-lasting colors and easy spray application (no milling required), it extends pavement lifespan while enhancing urban aesthetics.

Scope Of Application

Asphalt color changing pavement is a polyurethane color changing agent independently developed by the company, which can change any color on cement, asphalt concrete roads and various pavement boards. Compared with color anti-slip pavement, the construction process is simple, the cost is low, the sealing laver color is more bright, beautiful, the adhesion with the original surface layer is better, the strength, weather resistance, wear resistance is better. lts main component is polyurethane, which is significantly better than common acrylic and epoxy resin series in weather resistance, toughness, adhesion and plasticity, and the service life of ordinary landscape road can reach 10 years. The conventional spraying process can be used to spray directly on the surface of stable asphalt pavement, cementconcrete and sidewalk slab.

Product Features

1. can resist ultraviolet oxidation caused by surface aging, heat aging, anti-freeze thaw, weathering resistance, good durability;

2. rapid construction at room temperature, 1 hour after the construction ofthe bicycle can be on the road, 24 hours can be traffic, low temperature construction traffic time below 0℃ should be appropriately extended;

3. After spraying, the surface layer will no longer bond dust and particles, and the entire binder system has high strength and abrasion resistance, which is conducive to maintaining luster and beauty for a long time.

Construction Technology

1. Clean the surface ofthe road (asphalt concrete or cement concrete) to be changed, repair and smooth the damaged road surface, no loose, mesh cracks, collapses and pits, etc., and keep it completely dry;

2. ready the power supply and spraying machine, adjust the spraying pressure to 6-8MPa, first open the internal cycle to stir the spraying agent evenly;

3. after the spraying agent is stirred evenly, evenly sprayed on the road surface, generally spraying 2 times is appropriate, once spraying about half an hour later, and then spraying twice, 2 times to vertical (and a spraying direction in a cross) spraying;

4. After the spraying agent is completed each time, the spraying agent pipe should be thoroughly cleaned with thin material to prepare for the next use;

5. traffic time, 2 hours for human walking, 3 hours for non-motor vehicles, 12 hours for heavy vehicles.

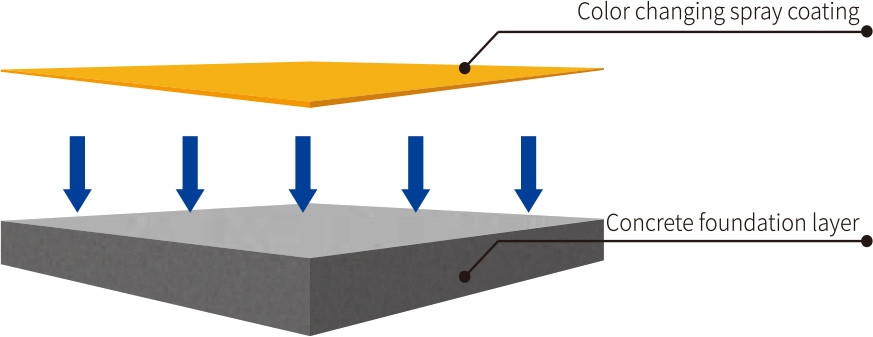

Construction Section Diagram

TECHNICAL INDEX

PILOT PROJECT | INDEX |

Drying time | Surface dry ≤ 4 hours |

Work ≤ 24 hours | |

Bond strength

| ≥ 0.5MPa |

Weather fastness | Pass the relevant weather resistance test standards |

| Water resistance | No significant change (after 7 days of immersion)

|

Compressive strength | ≥ 5 MPa |

Abrasion resistance | ≤ 0.5mm

|

| Friction coefficient | 0.4-0.6 |

| Ultraviolet resistance | ≥ 1000 hours without obvious fading |

| Chemical resistance | Pass the relevant chemical stability test standards |

Project Case