Water-Based Anti-Static Epoxy Floor Coating | Dustproof, Wear-Resistant Industrial Flooring

- Model

- PU-036

Review

Description

Information

Water-based Epoxy Anti-static Flooring Materials

Our water-based anti-static epoxy flooring is an eco-friendly, low-VOC solution designed for static-sensitive environments like electronics workshops, laboratories, and precision equipment facilities. With superior static dissipation (surface resistance 10^6-10^9Ω), it prevents electrostatic accumulation while offering high durability, abrasion resistance, chemical resistance, and easy maintenance. Fast curing and strong adhesion ensure safe, long-lasting performance.

Scope Of Application

Electronics, communication, printing, computer room, precision instrumentation, powder, chemical, Arsenal, aerospace and other areas need to be anti-static, especially suitable for wet environment construction.

Product Features

1. with water-based epoxy mortar (thick film) floor characteristics.

2. can quickly leak charge.

3. durable anti-static effect, not affected by time, temperature, humidity, etc.

4. the curing performance is less affected by humidity, and it has a good bonding effect on the wet surface.

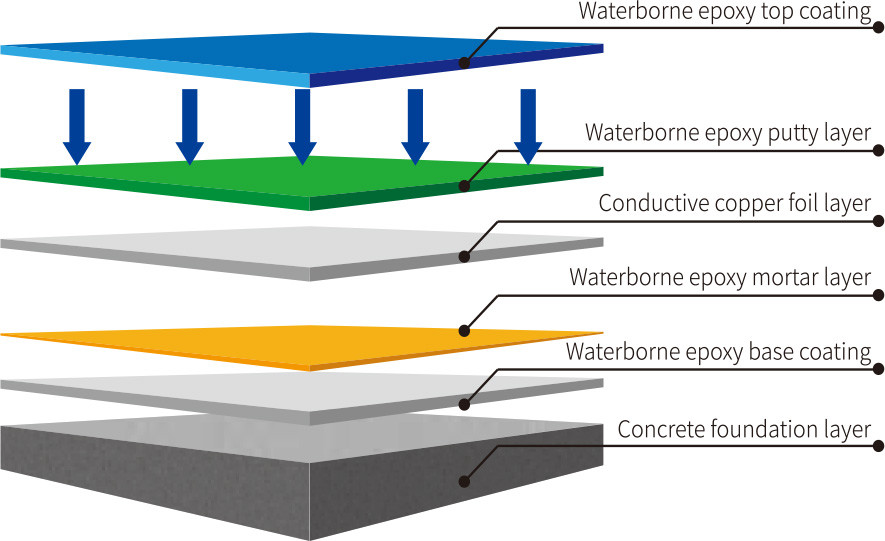

Construction Technology

1. Base surface treatment: polish the base surface, repair defects, clean and dry;

2. primer: paint epoxy primer;

3. Mortar: Use water-based anti-static epoxy medium coating material to deploy quartz sand to the thickness required for construction;

4. grounding copper foil: horizontal and longitudinal spacing 6m laying copper foil, grounding resistance< 10Ω;

5. batch scraping putty: use water-based anti-static epoxy coating material to deploy quartz powder or double fly powder scraping batch putty layer;

6. surface coating: Paint water-based self-leveling anti-static epoxy material.

Construction Section Diagram

TECHNICAL INDEX

PILOT PROJECT | INDEX |

Adhesion (grade) | ≤1 |

Pencil hardness (abrasion) | ≥2H |

| Wear resistance (700g/500r. Weight loss g) | ≤0.04 |

pliability | ≤2 |

| Resistance to 40%NaOH | No change in 7 days |

| Resistance to 30%H₂SO₄ | |

| Gasoline resistant 120# |

Project Case