Anti-Corrosion Epoxy Flooring - Acid & Chemical-Resistant Industrial Coating | Eco-Friendly & Long-Lasting

- Model

- PU-033

Review

Description

Information

Epoxy Anti-corrosion Flooring Material

Engineered for harsh environments like chemical plants and labs, our anti-corrosion epoxy flooring resists strong acids, alkalis, and organic solvents, certified for industrial safety. Non-porous surface blocks chemical penetration, ensuring long-term protection. Eco-friendly, fast-curing, and customizable in color/thickness. Ideal for factories, wastewater facilities, and high-risk zones.

Scope Of Application

Suitable for ships, Bridges, steel structure, plating factory, pharmaceutical factory, circuit board factory, power plant, sewage treatment plant, chemical storage tank (tank), battery factory and other places with anti-corrosion requirements.

Product Features

1. excellent mechanical properties, heat resistance, toughness and fatigue resistance.

2. the product has low viscosity, easy construction, can be cured at low temperature and the curing time can be adjusted.

3. below 100℃, can resist most of the acid, alkali, salt and other chemical agents erosion.

4. enough flatness and decoration.

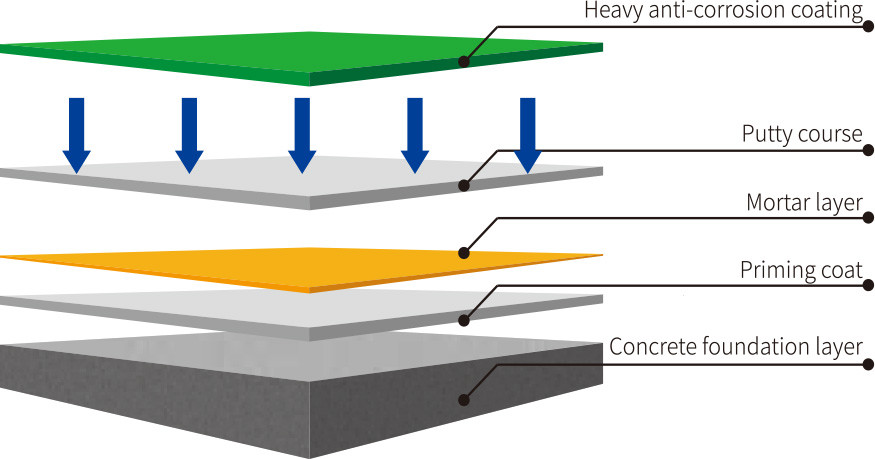

Construction Technology

1. Polish and clean the base surface.

2. paint epoxy resin primer.

3. batch scraping epoxy resin mortar.

4. batch scraping epoxy resin putty.

5. paint epoxy resin heavy anti-corrosion finish.

Construction Section Diagram

TECHNICAL INDEX

PILOT PROJECT | INDEX |

State in container | No hard pieces, uniform state |

Film appearance | The paint film looks normal |

Drying time (H,25°C) | Surface dry :≤6; Practical work :≤48 |

Shore hardness (Type D) | ≥75 |

Impact resistance (Class ll) | 1000g steel ball, height 100cm Coating film no cracks, no peeling |

Wear resistance (700g/500r. Weight loss g) | ≤0.030 |

Water resistance (168h) | Does not blister, does not flake, allows light Slight discoloration, recovered after 2 hours |

Hydrochloric acid resistance (20%HCL,72h) | Does not blister, does not flake, allows light microdiscoloration |

Sulfuric acid resistance (50%H₂SO₄,72h) | |

| Phosphoric acid resistance (20%HNO₃,72h) | |

Fruit acid resistance (15%,72h) | |

| Resistance to sodium hydroxide(40%NaOH,72h) | |

| Resistant oil, 72h | |

| Paint remover, 72 hours |

Project Case