Solvent-Free Epoxy Flooring Coating Eco-Friendly Durable Industrial & Commercial Floor Solution Non-Toxic High-Performance

- Model

- PU-028

Review

Description

Information

Solvent-free Epoxy Flooring Materials

Designed for industrial and commercial spaces, our solvent-free epoxy flooring coating is eco-friendly, non-toxic, and compliant with global safety standards. Offers high durability, chemical resistance, anti-slip properties, and rapid curing. Ideal for factories, warehouses, and parking lots. Customizable colors and textures with long-lasting gloss finish.

Scope Of Application

1. places with special requirements for environmental protection and smell;

2. the ground of supermarkets, halls, warehouses, auto showrooms, auto repair shops, parking lots and other places;

3. the ground of the place with high mechanical performance requirements, with a certain impact require-ments of mechanical electronics, electrical appliances, meters, medicine, textile, clothing, food, tobacco and other enterprises factory floor.

Product Features

High wear resistance and good scratch resistance. Strong impact resistance, resistant to chemicals. The whole system is solvation-free, large-area seamless construction, a construction of more than 2mm, high construction efficiency. Long service life of the system, easy maintenance of the top paint, not easy to bubble. Dustproof, moisture-proof, bacteria-proof, easy to clean, environmental protection.

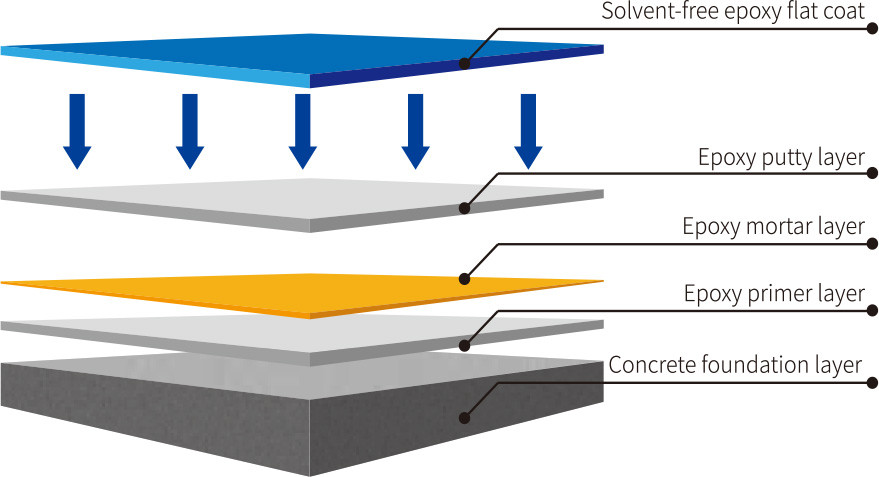

Construction Technology

1. plain treatment: according to the state of the base surface to do a good job of grinding, repair, dust;

2. Epoxy primer: Roll coating with epoxy primer with strong permeability and adhesion to enhance surface adhesion;

3. Epoxy mortar: Add the epoxy resin to the appropriate amount of quartz sand,and evenly coat it with a trowel;

4. epoxy putty: according to the actual needs of the construction of several, the requirements to achieve smooth without holes, no batch knife and sand printing shall prevail;

5. epoxy paint: solvent-free epoxy free-flow surface paint evenly troweled, after the completion of the overall ground to achieve bright and clean, uniformcolor, no empty drum;

6. Completion of construction: 24 hours before the person, 72 hours after the heavy pressure. (25°C shall prevail, low temperature opening time should be moderately extended)

Construction Section Diagram

TECHNICAL INDEX

| PILOT PROJECT | INDEX | |

State in container | No hard pieces, uniform state | |

Film appearance

| The paint film looks normal | |

Drying time (H,25°C) | Surface dry :≤6; Practical work :≤48 | |

Pencil hardness (H)

| ≥2H | |

Tensile bonding Strength,MPa | Standard condition | ≥2.0 |

After soaking | ≥2.0 | |

Compressive strength (MPa) | ≥45 | |

Wear resistance (700g/500r. Weight loss g) | ≤0.030 | |

Impact resistance (Class ll) | 1000g steel ball, height 100cm Coating film no cracks, no peeling | |

Coefficient of dry friction

| ≥0.50 | |

Volatile Organic Compounds (VOC)Mass concentrationa/(g/L) | ≤60 | |

Water resistance (168h)

| Does not blister, does not flake, allows light Slight discoloration, recovered after 2 hours | |

| Oil resistance (120# solvent gasoline, 72h)

| Does not blister, does not flake, allows light microdiscoloration | |

| Acid resistance (10%H₂SO₄, 48h)

| ||

| Alkaline resistance (20%Na0H,72h) | ||

Project Case