Epoxy Colored Sand Flooring Durable Slip-Resistant Decorative Coating for Industrial & Commercial Use

- Model

- PU-027

Review

Description

Information

Epoxy Colored Sand Flooring Material

We specialize in producing high-strength epoxy colored sand flooring materials, which are refined from environmentally friendly resins and natural colored sand. They have excellent wear resistance, corrosion resistance, and compression resistance, and are suitable for various scenarios such as factory workshops, commercial spaces, and underground garages. We offer 30+color customization options, with a matte, non slip surface that is easy to clean and has a lifespan of up to 15 years.

Scope Of Application

Requirements wear resistance, strong impact resistance, decorative luxury occasions, with a certain floor style, especially suitable for airports, large shopping malls, exhibition halls, subways, electronic communications, medical and health, luxury entertainment and commercial buildings, food production, offices and school laboratories pay attention to external cleaning, good durability places.

Product Features

1. Original paint film texture.

2. colorful.

3. any combination of color patterns.

4. good compressive capacity.

5. paint film permeabilityis good, natural conser-vation of the ground.

6. Show luxury.

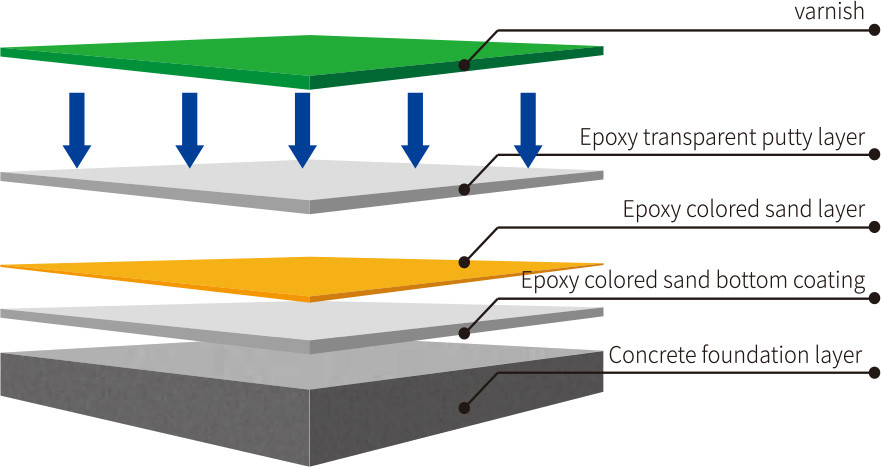

Construction Technology

1. the base surface treatment: grinding clean, the base surface requires dry, smooth, no empty drum;

2. epoxy sand special primer closed coating;

3. epoxy sand construction;

4. remove the floating sand, batch scraping epoxy transparent putty;

5. varnish cover light.

Construction Section Diagram

TECHNICAL INDEX

| PILOT PROJECT | INDEX | |

| State in container | No hard pieces, uniform state | |

| Film appearance | The paint film looks normal | |

| Drying time (H,25°C) | Surface dry :≤6; Practical work :≤48 | |

Shore hardness (H) | ≥75 | |

Tensile bonding Strength,MPa | Standard condition | ≥2.0 |

After soaking | ≥2.0

| |

Compressive strength (MPa) | ≥45 | |

Wear resistance (700g/500r. Weight loss g) | ≤0.030 | |

Impact resistance (Class ll) | 1000g steel ball, height 100cm Coating film no cracks, no peeling | |

Coefficient of dry friction | ≥0.50 | |

Water resistance (168h) | Does not blister, does not flake, allows light Slight discoloration, recovered after 2 hours | |

Oil resistance (120# solvent gasoline, 72h) | Does not blister, does not flake, allows light microdiscoloration | |

Acid resistance (10%H₂SO₄, 48h) | ||

Alkaline resistance (20%Na0H,72h) | ||

Project Case