Antistatic Self-Leveling Epoxy Flooring | ESD-Safe & Seamless Cleanroom Coating System

- Model

- PU-026

Review

Description

Information

Epoxy Anti-static Self-leveling Flooring Materials

This anti-static epoxy self-leveling flooring material is designed for industrial plants, electronic workshops, and data centers. Utilizing conductive carbon fiber and epoxy resin composite technology, it delivers stable ESD performance (surface resistance 10^6-10^9Ω). Features high abrasion resistance (load capacity ≥80MPa), seamless application, and chemical corrosion resistance.Ideal for cleanrooms, medical labs, and precision environments.

Scope Of Application

It requires highly clean, beautiful, dust-free, sterile and anti-static electronics, microelectronics, communication products, electronic production industries, factories, etc.

Product Features

1. the antistatic effect is excellent and durable, not affected by time, temperature, humidity, etc.

2. the selection of solvent-free epoxy resin and high-quality curing agent made.

3. smooth surface, beautiful, mirror-like effect.

4. wear resistance, alkali, salt, oil corrosion, especially good alkali resistance.

5. wear resistance, pressure resistance, impact resistance, there is a certain elasticity.

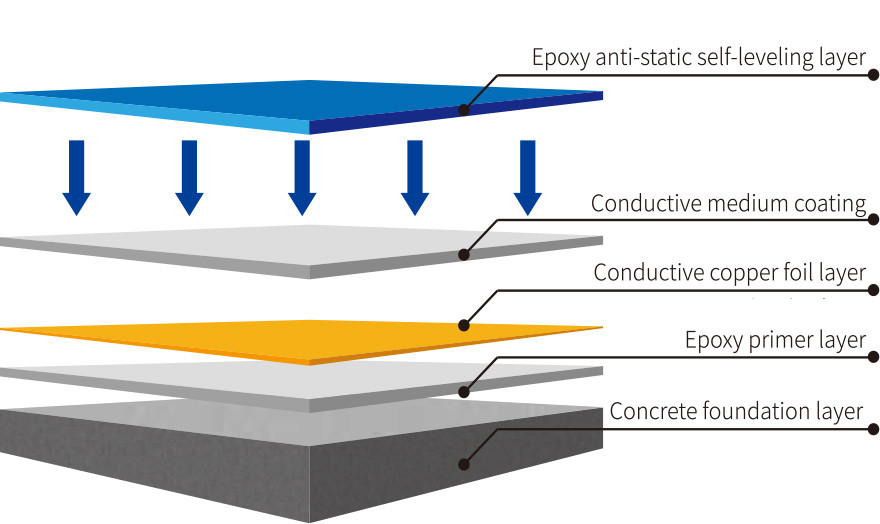

Construction Technology

1. base surface treatment.

2. Paint the sealing primer.

3. laying copper wire, cutting groove.

4. Scrape conductive intermediate paint.

5. Grinding and vacuuming.

6. Apply 1-2 times with epoxy anti-static self-leveling paint trowel.

Construction Section Diagram

TECHNICAL INDEX

| PILOT PROJECT | INDEX | |

State in container | No hard pieces, uniform state | |

Film appearance | The paint film looks normal | |

Drying time (H,25°C) | Surface dry :≤6; Practical work :≤48 | |

Shore hardness (H) | ≥70 | |

Tensile bonding Strength,MPa | Standard condition

| ≥2.0 |

After soaking | ≥2.0 | |

Compressive strength (MPa) | ≥45 | |

Wear resistance (700g/500r. Weight loss g) | ≤0.030 | |

Impact resistance (Class ll) | 1000g steel ball, height 100cm Coating film no cracks, no peeling | |

Coefficient of dry friction | ≥0.50 | |

Water resistance (168h) | Does not blister, does not flake, allows light Slight discoloration, recovered after 2 hours | |

Oil resistance (120# solvent gasoline, 72h) | Does not blister, does not flake, allows light microdiscoloration | |

| Acid resistance (10%H₂SO₄, 48h) | ||

| Alkaline resistance (20%Na0H,72h) | ||

| Surface resistance (Ω) | 10⁶-10⁹ | |

Volume resistance (Ω) | 10⁶-10⁹ | |

Project Case