Composite Rubber Track Material | IAAF-Certified Anti-Slip Surface for Schools & Stadiums

- Model

- PU-004

Item specifics

- Color

- red, blue, green, yellow, white, etc

Review

Description

Information

Composite Plastic Track Material

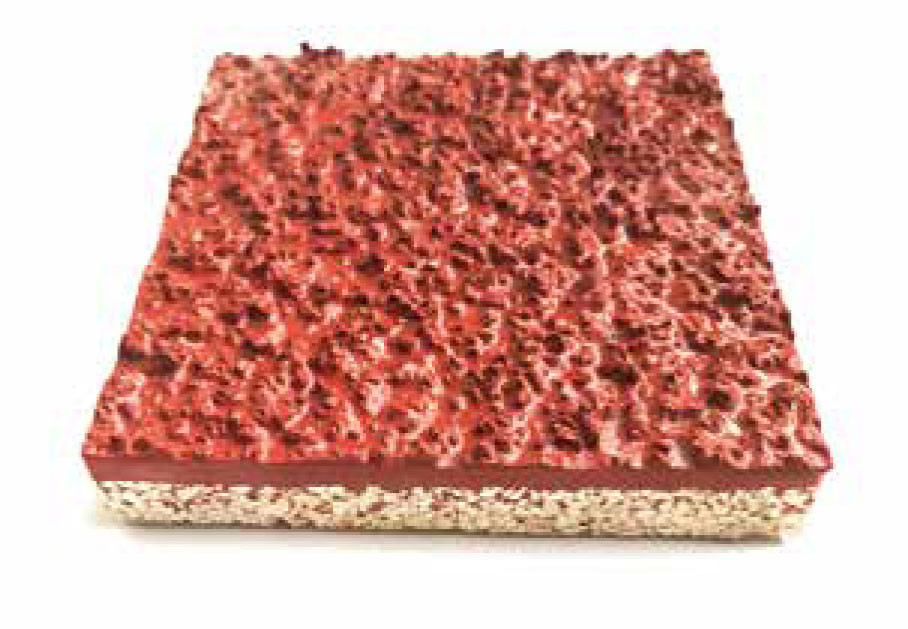

The composite plastic track is divided into two layers.The bottom layer is the same as the breathable plastic track.The elastic rubber particles and the polyurethane adhesive are made of cushioning equipment to form a cushion elastic layer with a thickness of 8mm.The PU polyurethane elastic layer is laid with a thickness of 2-3mm.Spray the finish of the runway as a wear surface.

Scope Of Application

1. Track and field runways of universities, middle schools and primary schools;

2. Non professional training track;

3. Sports Park, fitness venue runway (200m,300m,400m recommended)

Product Features

1. Good elasticity

2. High strength

3. Wear resistant

4. Vibrant color

5. Moisture prevention

6. Sound insulation

7. Durable and long-lasting

8. Low cost

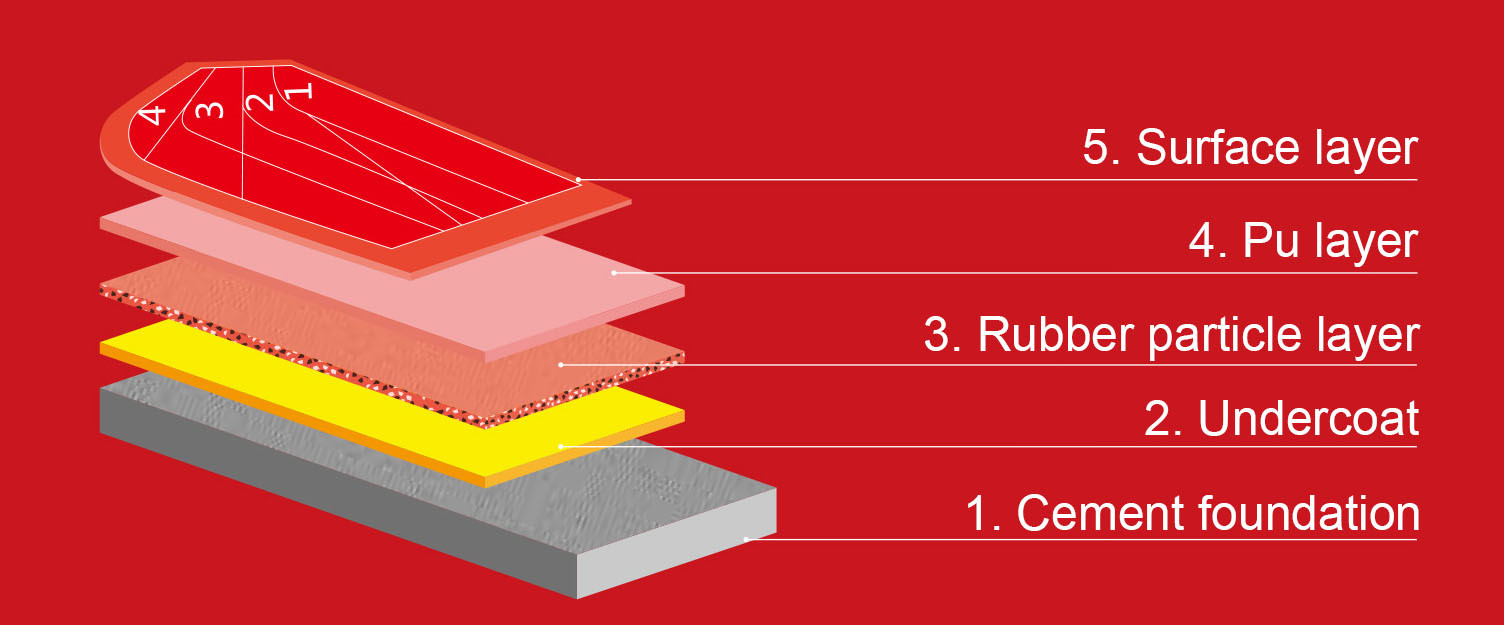

Layered Diagram

Material Parameter

| Composite Plastic Track Material Parameter | |

Parameter Name | Parameter Value |

Main Ingredients | Polyether Polyol,Isocyanate,EPDM |

Density | 1-1.3g/cm³ |

Polymer Content | 30-40% |

Shore A Hardness | ≥45 |

Tensile Strength (Mpa) | ≥0.6 |

Fracture Elongation Rate /% | ≥50 |

Vertical Deformation /mm | 1.0-3.0 |

Thickness | Average thickness 13mm, minimum not less than 10mm |

Slope Requirements | Longitudinal slope ≤ 0.1%, transverse slope ≤ 1.0% |

Evenness | The gap under a 2-meter straightedge shall not exceed 3mm. |

| Drainage Performance | Non permeable type |

Heavy metals (lead, chromium, cadmium, mercury) /mg/kg | ≤2 |

Flame Retardancy | I |

TVOC Emissions mg/(㎡. h) | ≤5.0 |

Weather Resistance | Aging box 500H, performance qualified |

| Nail Resistance | Anti spiked shoes |

| Anti Slip Value (BPN. 20 ℃) | 90-110 (Dry Test) |

Ingredient List

| Composite Plastic Track Ingredient List

13mm Plastic Track | |||

| Name Of Proportioning Material | Model | Packaging Specifications | Net Weight |

Single component adhesive (base) | LS-002 | 200L 570mm diameter x 890mm height | 200kg/barrel |

Available granules: black granules (2-4mm), red or white EPDM granules (2-4mm) or else color granules | LS-032 | / | 25kg/bag |

EDPM Adhesive Powder | LS-033 | / | 25kg/bag |

Single component adhesive | LS-003 | 200L

570mm diameter x 890mm height | 200kg/barrel |

Runway material PU | LS-005 | A:200L, B:300L 570mm diameter x 890mm height | A:200kg/barrel,B:300kg/barrel |

Running Track Topcoat Red/Green/Blue | LS-007 | A:200L, B:250L 570mm diameter x 890mm height | A:200kg/barrel,B:250kg/barrel |

EPDM granules (1-3mm) | LS-026 | / | 25kg/bag |

Eco-friendly Catalytic Agent | LS-009 | 275mm base diameter * 285mm surface diameter * 362mm height or else | 20KG/barrel or else |

Eco-friendly Diluent | LS-010 | 20L or 200L 275mm base diameter * 285mm surface diameter * 362mm height or 570mm diameter x 890mm height | 20KG/barrel or 200kg/barrel |

Marking Paint | LS-011 | 5L | 5.1kg/barrel |

Lead time (within days) | 1-7 days, usually within 24 hours | ||

| Sales Method | Sell all materials for the ingredient list | ||

Product Certificate