EPDM Eco-Friendly Running Track Material - UV Resistant, Non-Toxic & High Elasticity, Child-Safe

- Model

- PU-001

Item specifics

- Color

- red, blue, green, yellow, white, etc

Review

Description

Information

EPDM Eco-Friendly Running Track

EPDM surfaces are constructed using EPDM granules, which are composed of ethylene-propylene-diene monomer (EPDM), a terpolymer of ethylene, propylene, and non-conjugated diene. Commercial production of EPDM began in 1963. As a novel high-molecular synthetic material developed for flooring applications, EPDM flooring exhibits outstanding aging resistance, electrical insulation properties, and ozone resistance. When installed, it forms a seamless, integrated surface without joints.

Scope Of Application

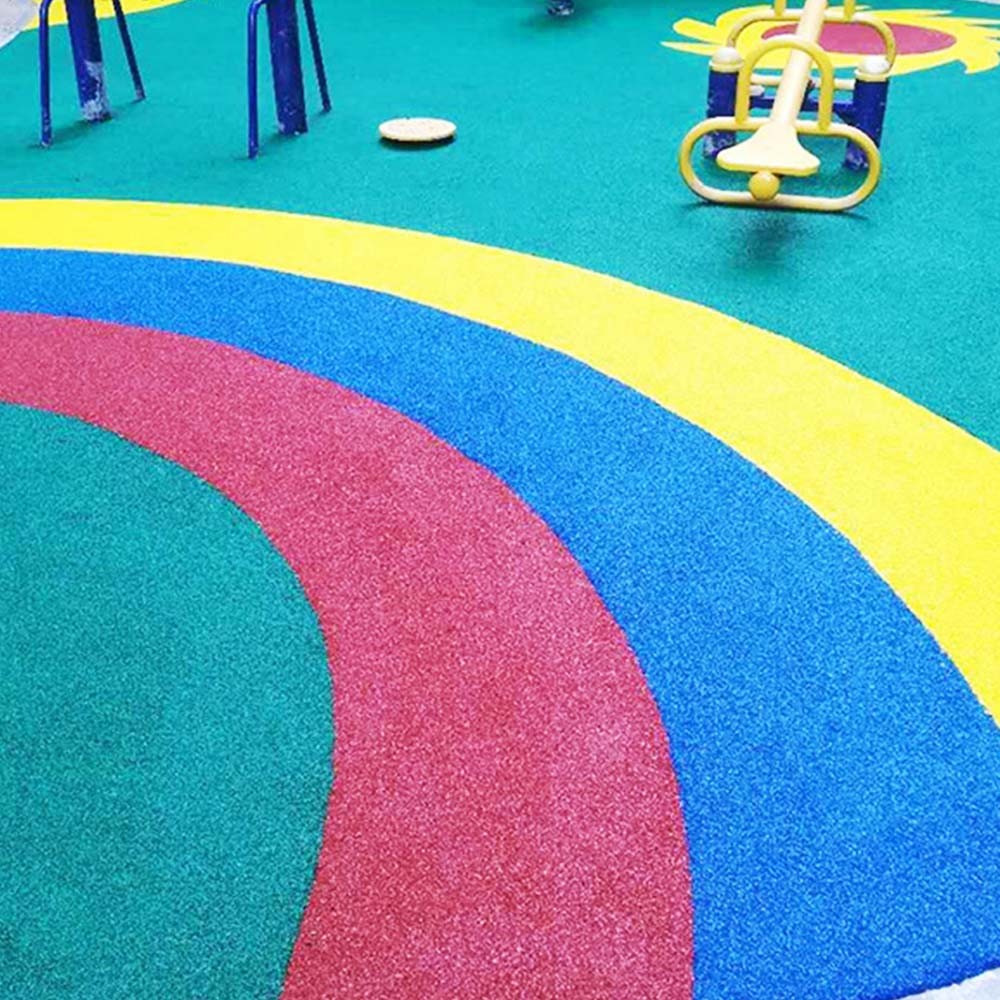

lt is applicable to all kinds of schools at all levels of kindergartens, professional stadiums, track andfield runways, semicircle areas, auxiliary areas, national fitness paths, indoor gymnasium training runways, playground road pavement, indoor and outdoor runways, tennis, basketball, volleyball.badminton, handball and other venues, parks, residential areas and other activity venues.

Product Features

1. Breathable and permeable

2. Good elasticity

3. Good flatness

4. Good weather resistance

5. Strong wear resistance

6. Do not thresh

7. Diverse colors

8. Durable and sturdy

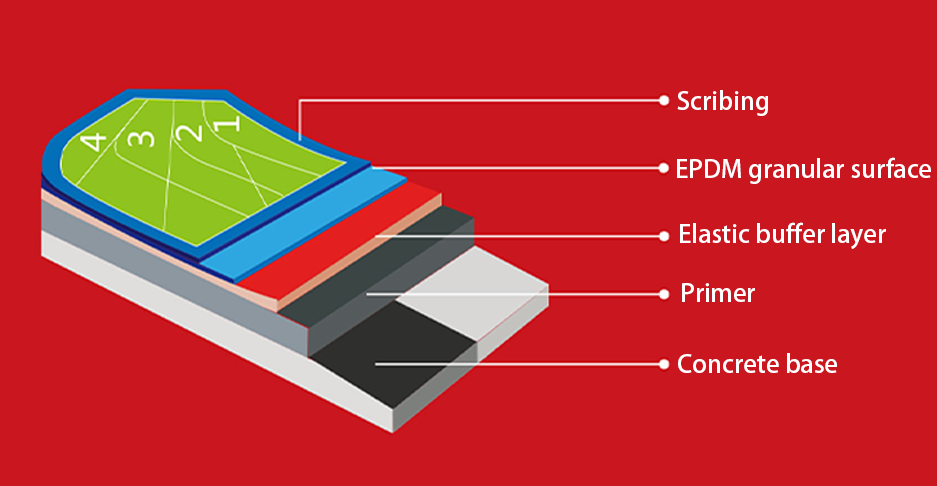

Layered Diagram

Environmentally friendly EPDM rubber granules

Material Advantages

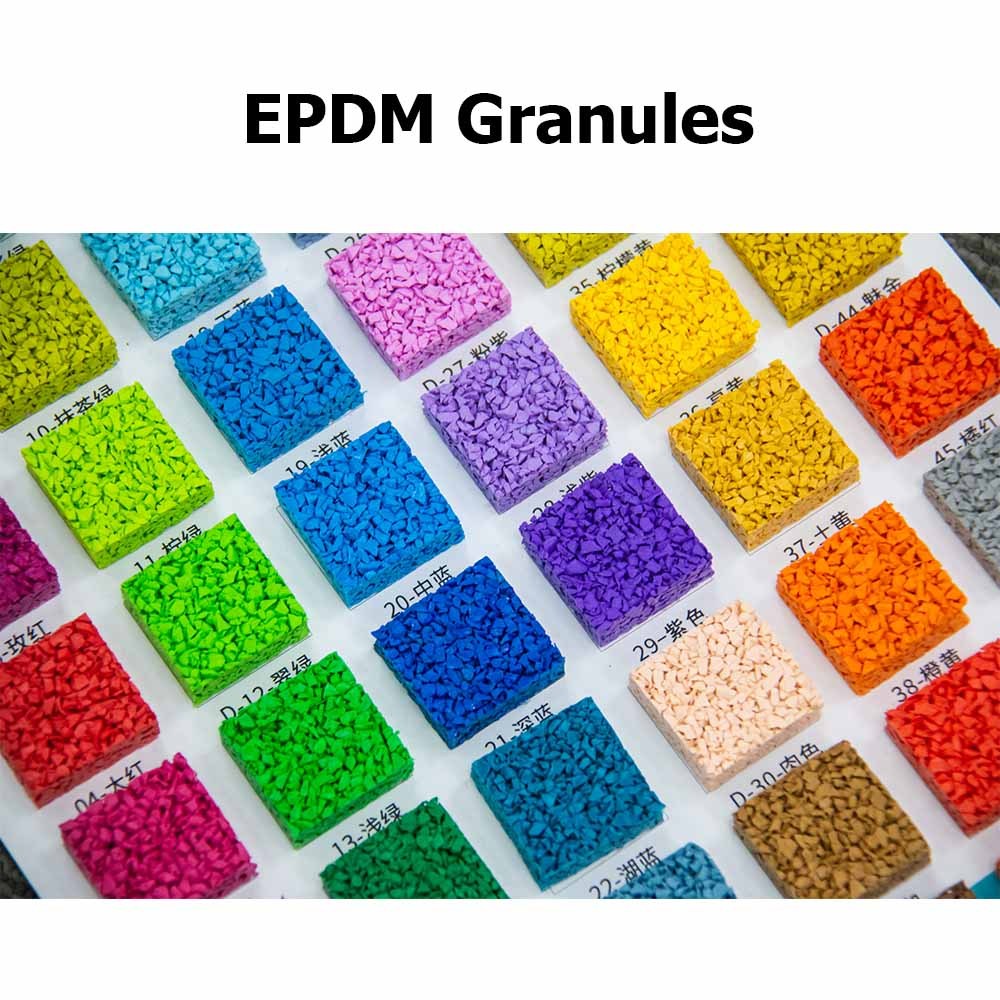

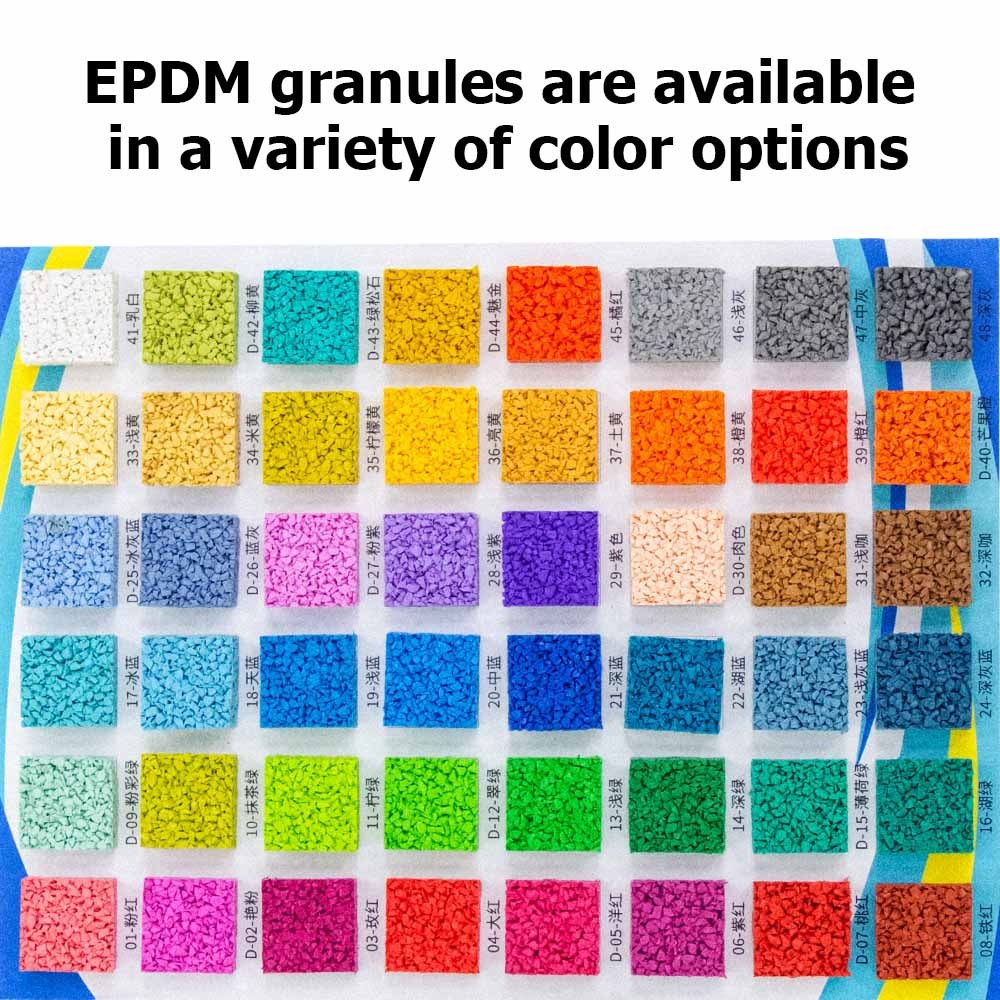

EPDM granules are made of synthetic rubber and can be produced in various colors, demonstrating excellent resistance to UV radiation and general chemical reactions. Their superiority is particularly evident in patterned field construction.

1. Chemical Stability: The product exhibits high corrosion resistance and exceptional chemical stability, with outstanding resistance to ozone aging and thermal-oxidative aging.

2. Excellent Elasticity: It maintains remarkable elasticity even at low temperatures.

3. Strong Adhesion: Demonstrates superior bonding properties.

4. Vibrant Colors: The granules feature stable, colorfast hues with high UV resistance and weather durability.

5. Customizable Production: Can be tailored to meet user-specific requirements, including color, particle size, and rubber content, ensuring diverse customer needs are fulfilled.

Material Parameter

EPDM Eco-Friendly Running Track Material Parameter | |

Parameter Name | Parameter Value |

Main Ingredients | Polyether Polyol,Isocyanate,EPDM |

Density | 1-1.5g/cm³

|

Polymer Content | 20-30% |

Shore A Hardness | ≥45 |

Tensile Strength (Mpa) | ≥0.5 |

Fracture Elongation Rate /% | ≥40 |

Vertical Deformation /mm | 1.0-3.0 |

Thickness | Average thickness 13mm, minimum not less than 10mm |

Slope Requirements | Longitudinal slope ≤ 0.1%, transverse slope ≤ 1.0% |

Evenness | The gap under a 2-meter straightedge shall not exceed 3mm. |

| Drainage Performance | Permeable Type |

Heavy metals (lead, chromium, cadmium, mercury) /mg/kg | ≤2 |

Flame Retardancy | I |

TVOC Emissions mg/(㎡. h) | ≤5.0 |

| Weather Resistance | Aging box 500H, performance qualified |

| Nail Resistance | Not resistant to nail shoes |

| Anti Slip Value (BPN. 20 ℃) | 90-110 (Dry Test) |

Material List

| EPDM Eco-Friendly Running Track Ingredient List

13mm EPDM Plastic Flooring | |||

Name Of Proportioning Material | Model | Packaging Specifications | Net Weight |

Single component adhesive (base) | LS-002 | 200L 570mm diameter x 890mm height | 200kg/barrel |

Available granules: colored granules (2-4mm), white EPDM granules (2-4mm), black granules (2-4mm) | LS-032

| / | 25kg/bag |

Single component adhesive | LS-003 | 200L 570mm diameter x 890mm height | 200kg/barrel |

EPDM granules (1-3mm) | LS-026 | / | 25kg/bag |

| Eco-friendly Diluent | LS-010 | 20L or 200L 275mm base diameter * 285mm surface diameter * 362mm height or 570mm diameter x 890mm height | 20KG/barrel or 200kg/barrel |

Line marking paint | LS-011 | 5L | 5.1kg/barrel |

| Lead time (within days) | 1-7 days, usually within 24 hours | ||

| Sales Method | Sell all materials for the ingredient list | ||

Project Case

Product Certificate