AGV Flooring System Solutions by PaintUniverse: Durability Meets Automation

- Share

- publisher

- Molly

- Issue Time

- Jul 22,2025

Summary

Durable AGV flooring systems by PaintUniverse. Anti-static, high-load, seamless resin floors for smart factories worldwide.

AGV Driving Area Flooring System Solution

As industrial automation advances, Automated Guided Vehicles (AGVs) are transforming warehouses, logistics centers, and manufacturing plants across sectors such as automotive, electronics, pharmaceuticals, and photovoltaics. However, one often overlooked but crucial factor in successful AGV operation is the flooring system beneath the wheels.

At PaintUniverse, a global brand under Guangdong Lvshu Group with over a decade of manufacturing and R&D expertise, we specialize in providing durable, high-performance flooring systems tailored for AGV driving areas. This blog outlines key challenges, system requirements, and our comprehensive flooring solutions for AGV applications.

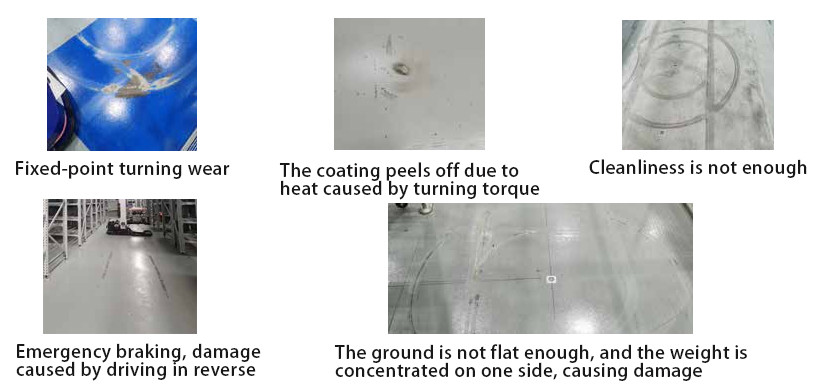

Common Flooring Failures in AGV Areas

- Surface cracking and delamination due to high point loads

- Abrasion and coating wear caused by repeated turning

- Impact damage from emergency braking or reversing

- Surface unevenness leading to AGV guidance errors

- Static discharge risks in sensitive electronics environments

What AGV Driving Areas Demand from Flooring Systems

- Superior load-bearing capacity

- High abrasion resistance

- Crack-free and bubble-free construction

- Seamless and jointless design

- Exceptional flatness and levelness

- Anti-slip and cleanable surface

- Optional anti-static and chemical-resistant properties

PaintUniverse AGV Flooring System Solutions

1. Optimized Concrete Base

We provide ultra-flat, high-strength concrete slabs using our proprietary mix design and reinforcement strategy. By incorporating shrinkage reducers, steel/poly fibers, and dry-shake hardeners, we ensure:

- No cracking or delamination

- Stable curing and low shrinkage

- Superior surface strength and durability

We also offer precast expansion joint solutions made from polyurethane resin mortar, designed to withstand heavy dynamic loads from AGVs, reduce vibrations, and minimize tire wear.

2. High-Performance Coating Systems

▶ For Heavy-Duty AGV Zones (Over 1000 KG Load)

- 4–6mm Anti-Static Polyurethane Mortar Self-Leveling System

- 10mm Epoxy Color Sand System

Benefits:

- Long-lasting anti-static protection

- High wear resistance

- Ultra-smooth and easy-to-clean surface

- Solvent-free and eco-friendly

▶ For Medium Load Zones (500–1000 KG)

- 2mm Anti-Static Epoxy System

- 2–3mm Polyurethane Mortar System

▶ For Light-Duty Zones (Below 500 KG)

- 2mm Anti-Static Epoxy Floor

- 3mm Epoxy Color Sand System

▶ For General Use, All Load Classes

Using dry-shake hardeners such as PaintUniverse SAP/MAP, this is a cost-effective and durable option for logistics centers and manufacturing facilities.

Why Choose PaintUniverse?

As the export brand of Guangdong Lvshu Group, PaintUniverse stands at the forefront of industrial flooring innovation. Our company combines R&D, production, and sales, offering customized flooring systems for AGV and intelligent manufacturing facilities worldwide.

🌐 Learn more about us:

www.paintuniverse.cn/aboutus.htm

With a strong presence in Southeast Asia, the Middle East, Africa, and Oceania, PaintUniverse is your trusted partner for sustainable, high-performance AGV flooring solutions.

Final Thoughts

As AGVs become integral to modern logistics and smart factories, flooring systems must evolve to match their demands. PaintUniverse's AGV driving area flooring systems offer the durability, functionality, and customization your facility needs to support safe, efficient automation.

📩 Contact us today to discuss your AGV floor project or request a custom technical proposal.